Residual stress measured in feed direction by X-ray diffraction (XRD) indicated that the conditions of machined Al6063 surface were all tensile, while the conditions of Al/SiC/65p were compressive. The results of single-factor experiment demonstrated that surface roughness improved slightly with the decrease in the feed rate, while the effect of milling speed was negligible. In terms of residual stress on the machined surface, axial depth of cut had the highest influences on surface residual stress, followed by milling speed and feed rate.

The results of full factorial experiment revealed that the most significant milling parameter for surface roughness was milling speed, followed by the interaction between feed rate and milling speed, then the feed rate. In addition, the experiments on corresponding unreinforced matrix alloy Al 6063 were also carried out to analyze the influence of the present reinforcements on surface integrity. The influences of cutting parameters on surface roughness (Ra), surface residual stress (RS) and morphology of PRAMCs were investigated.

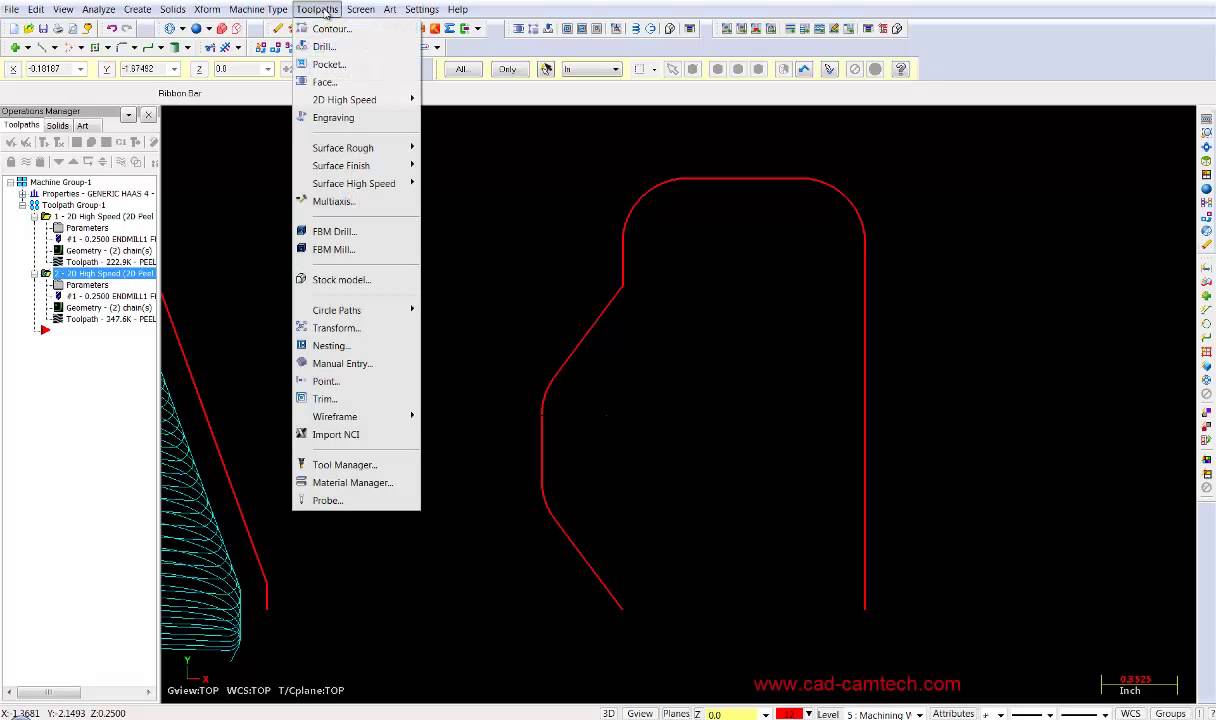

This paper presents a systematic experimental research of high speed milling of Al/SiC/65p (65% volume fraction) by polycrystalline diamond tools (PCD). Therefore, the increasing applications of PRAMCs necessitate an in-depth understanding of the variation law of surface integrity. The surface quality of components produced through milling of particle reinforced aluminum matrix composites (PRAMCs) is one of the most important factors influencing their practical performance. 5 New Power Libraries in Mastercam X4 Wire Add-On Feature. 7 In-Depth Look at Dynamic Planes Mold design courtesy of R&B Mold and Design. 4 What Else is New in Mastercam X4 Lathe Design Feature. We hope you find this new product as exciting for your shop as we do! Lathe Feature. This issue of Mastercam Notes focuses on the new Mastercam for SolidWorks product by explaining exactly what it is, describing the process, and backing it up with a few customer testimonials. This means users can now program their parts directly within SolidWorks using the toolpaths and machining strategies preferred by shops around the world. Mastercam X4 for SolidWorks brings the world’s leading modeling software together with the world’s most widely-used CAM software. 6 High Speed Machining with Router Mastercam®X4 for SolidWorks® To Be Released CNC Software is proud to introduce the latest in its line of powerful Mastercam machining software – fully integrated CAM that runs seamlessly within SolidWorks.

2-3 What Exactly is Mastercam for SolidWorks? Router Feature. Third Quarter 2009 Product Highlights Mill Feature.

0 kommentar(er)

0 kommentar(er)